Vessel in Australia

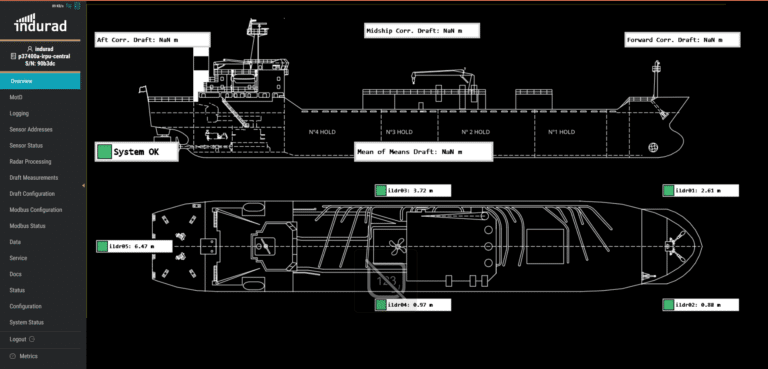

A custom iBerth solution is utilized on a vessel in Australia to detect rolling, trimming and bowing during loading operations. This ensures that the vessel is loaded correctly, while providing the crew with the necessary information to monitor the loading process and the vessel’s movement. This contributes to avoiding any damage to the ship’s structure.

iBerth On Vessel

A vessel that travels usually short distances and docks once or twice per day was equipped with an iBerth system to have all the information that iBerth provides, independent of the harbor infrastructure.

This information helps the crew to navigate and dock the vessel faster and safer – especially in difficult weather situations where visibility is limited, at night times, in narrow ports or during berthing in thick fog.

Ship drift in Australia

In Australia, at a place where the highest tidal changes can be found, the solution supports operations in two ways:

- It provides a drift detection of the vessels at berth. This provides a massive improvement in safety for daily operations. The picture on the left shows a measured ship drift of 89 cm, causing an alarm.

- Besides this, the solution provides data about the position of the incoming vessel – which supports docking activities.

Unique data for harbout management systems

A port in Brazil uses the iBerth solution as an asset to their harbour management system. indurad provides data:

- distance of Bow

- distance of stern

- speed

- approach angle

In combination with further datapoints such as:

- vessel type and loading

- wind speed

- tide

the system provides a full set of information to the operators, increasing efficiency and safety in daily operations as well as in special conditions where operations are more difficult to perform (e.g., high tide, low tide, strong rain and thunderstorms etc.).