REVOLUTIONIZING THE BULK MATERIAL VALUE CHAIN WITH INDURAD'S MODULAR SMART RADAR SOLUTIONS

DISCOVER OUR CUSTOMIZED SOLUTIONS FOR EVERY SECTOR

DISCOVER OUR CUSTOMIZED SOLUTIONS FOR EVERY SECTOR OF THE BULK MATERIAL VALUE CHAIN.

Understanding that each sector within the mining- and bulk material value chain has its own set of complexities and requirements, we have developed modular software solutions that cater to the specific needs of each branch. Whether it‘s mining, processing, logistics, or stockyard management, our software possesses an in-depth knowledge of industry-specific dynamics, enabling it to provide actionable insights that drive safety, efficiency, and productivity.

offering

indurad delivers a full-scope portfolio of high-value, tailored solutions for mining, processing, and port operations, incorporating complex kinematic machine models for precision and efficiency.

scope

Our solutions include hardware integrated with customized software, engineering services, remote commissioning, and ongoing maintenance through Service Level Agreements (SLAs), ensuring continuous optimization.

market

indurad’s primary focus is on serving mining clients across a wide range of commodities, providing adaptable and scalable solutions for diverse industry needs.

Anti Collision

Inventory Control

Positioning | Localization

Digitalization | IoT

Process | Optimization

Operator Assistance

Remote Operation

Advanced Automation

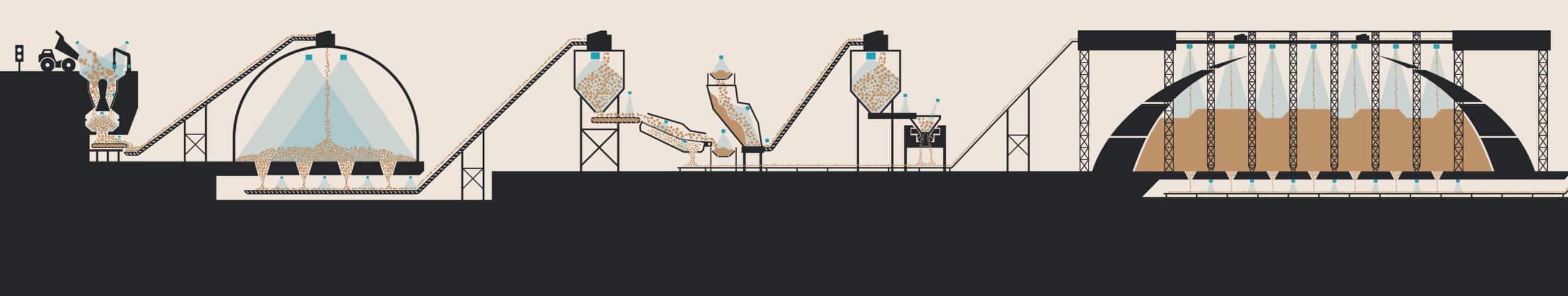

MINE PROCESSING

MINE PROCESSING

MINE FEED

Significant reduction in blockages & downtime

BULK FLOW IN PLANT

Increased throughput via analytics & automation

BULK VOLUME

Uninterrupted 3D inventory &quality control

Solution Group

MINE FEED

Solution Group

BULK FLOW

Solution Group

BULK VOLUME

MINE FEED

Solution Group

MINE FEED

BULK FLOW IN PLANT

Solution Group

BULK FLOW

BULK VOLUME

Solution Group

BULK VOLUME

BULK LOGISTICS

BULK LOGISTICS

TRAIN LOGISTICS

Increased payloads & reduced waste

STOCKYARD MANAGEMENT

Enhanced efficiency via remote control & automation

SHIPLOADING

Make outload safe, fast, planable

Solution Group

STOCKYARD

Solution Group

SHIPLOADING

TRAIN LOGISTICS

STOCKYARD MANAGEMENT

Solution Group

STOCKYARD

SHIPLOADING

Solution Group

SHIPLOADING

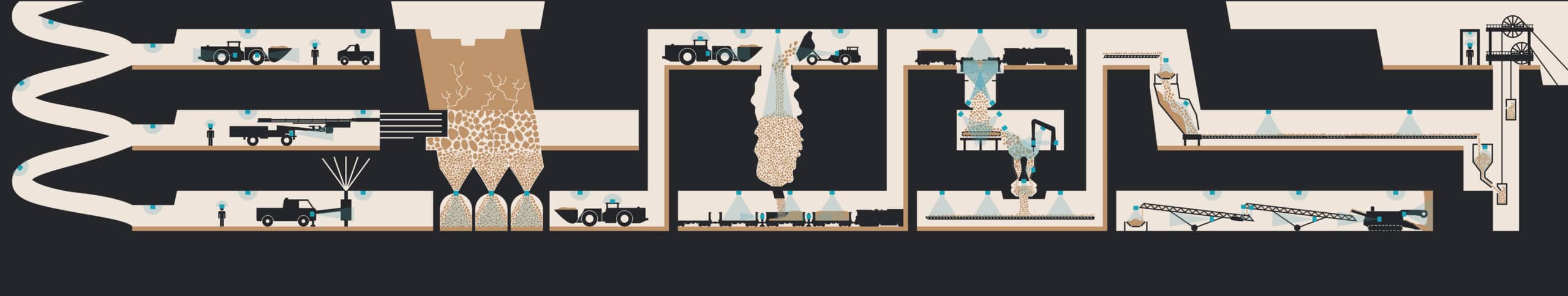

UNDERGROUND MINING

UNDERGROUND MINING

COLLISION AVOIDANCE

Safety & operator guidance

PRODUCTION & AUTOMATION

Increased throughput via debottlenecking

CONTINUOUS HAULAGE

Monitoring and control of conveyor and transfer points

Solution Group

CAS/PDS

Solution Group

PRODUCTION & AUTOMATION

Solution Group

CONTINUOUS HAULAGE

COLLISION AVOIDANCE

Solution Group

CAS/POS

PRODUCTION & AUTOMATION

Solution Group

PRODUCTION & AUTOMATION

CONTINUOUS HAULAGE

Solution Group

CONTINUOUS HAULAGE

Low Visibility

Snow

Water

Extreme Contamination

Heat

Sand | Sandstorms

Dust

Explosive Environment

Rain

Ice | Cold