You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationA Quantum Leap for Bulk Terminals

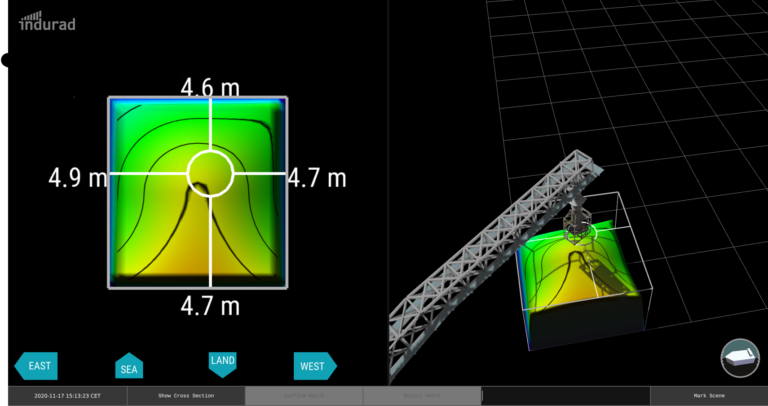

To improve port operations, EECV Rotterdam is using a combination of Indurad solutions.

Learn how the customer uses the solutions for individual benefits and how they are combined for a quantum leap in bulk terminal operations.