Oil Sand

COUNTRY: Canada

MATERIAL: Oil Sand / Tar Sand

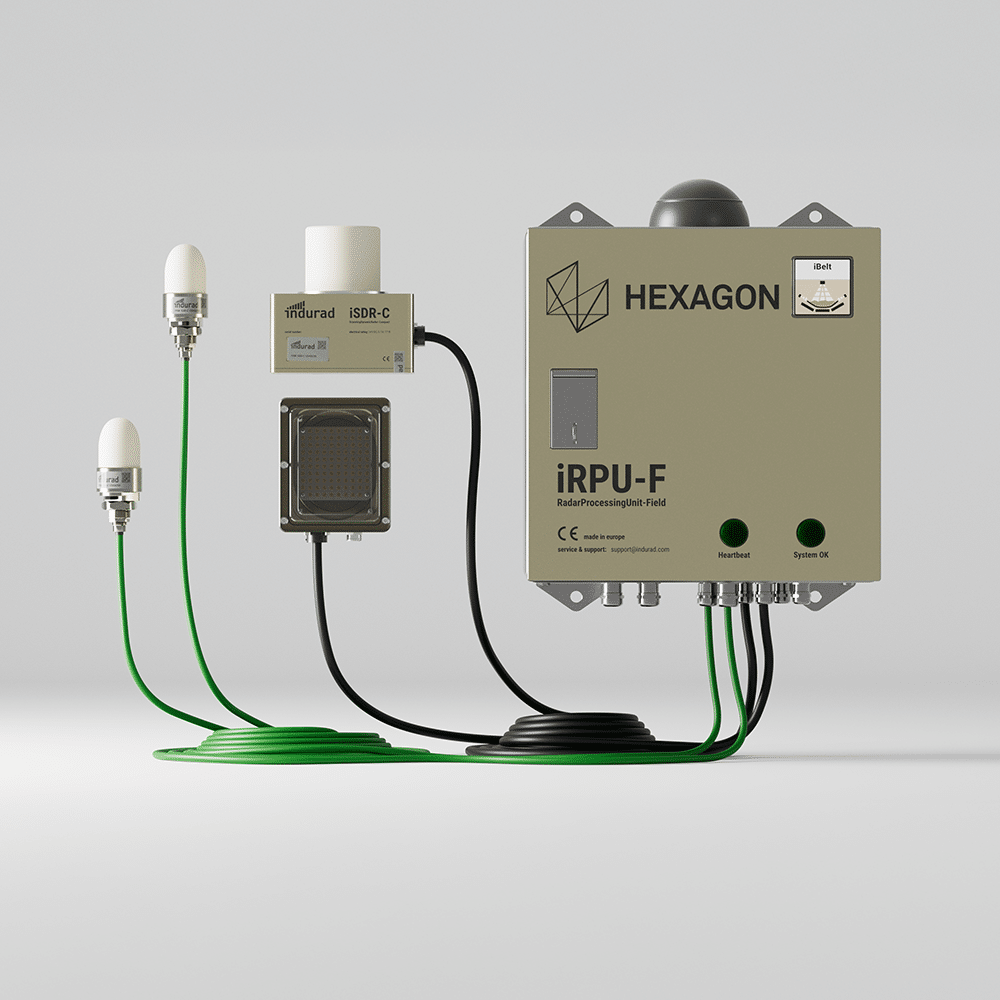

COMPONENTS: 2x iLDR-C, iSDR-C, iDVR, iRPU-F

DESCRIPTION

Volumetric flow measurement and belt alignment tracking.

Extreme environmental conditions (dirt, temperature).

The iBelt system enhances conveyor operations with high-speed 2D radar scanning for accurate volume flow measurement, capturing cross-sectional views, and providing height and material distribution insights. Its radar-based, contactless speed measurement delivers milimeter accuracy, optimizing belt speeds and preventing slippage without needing recalibration. The iBelt Misalignment feature detects belt misalignment, reducing wear, energy consumption, and spillage risks. Additionally, its freeboard measurement ensures optimal material positioning, minimizing wear and enhancing belt longevity and safety. Overall, iBelt ensures efficient, safe, and cost-effective material handling.

Volume flow measurement / Material speed measurement / Belt alignement measurement / Material freeboiard measurement / Center of gravity & loading peak calculation

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationHigh precision (up to 97%) and reliability without the need for recalibration or maintenance.

Easy installation and commissioning within one shift using a software wizard and calibration tools.

Applicable to all bulk commodities and harsh environments, enhancing versatility and durability.

iBelt leverages a robust network of maintenance-free radar sensors and auxiliary components, designed for harsh mining environments.

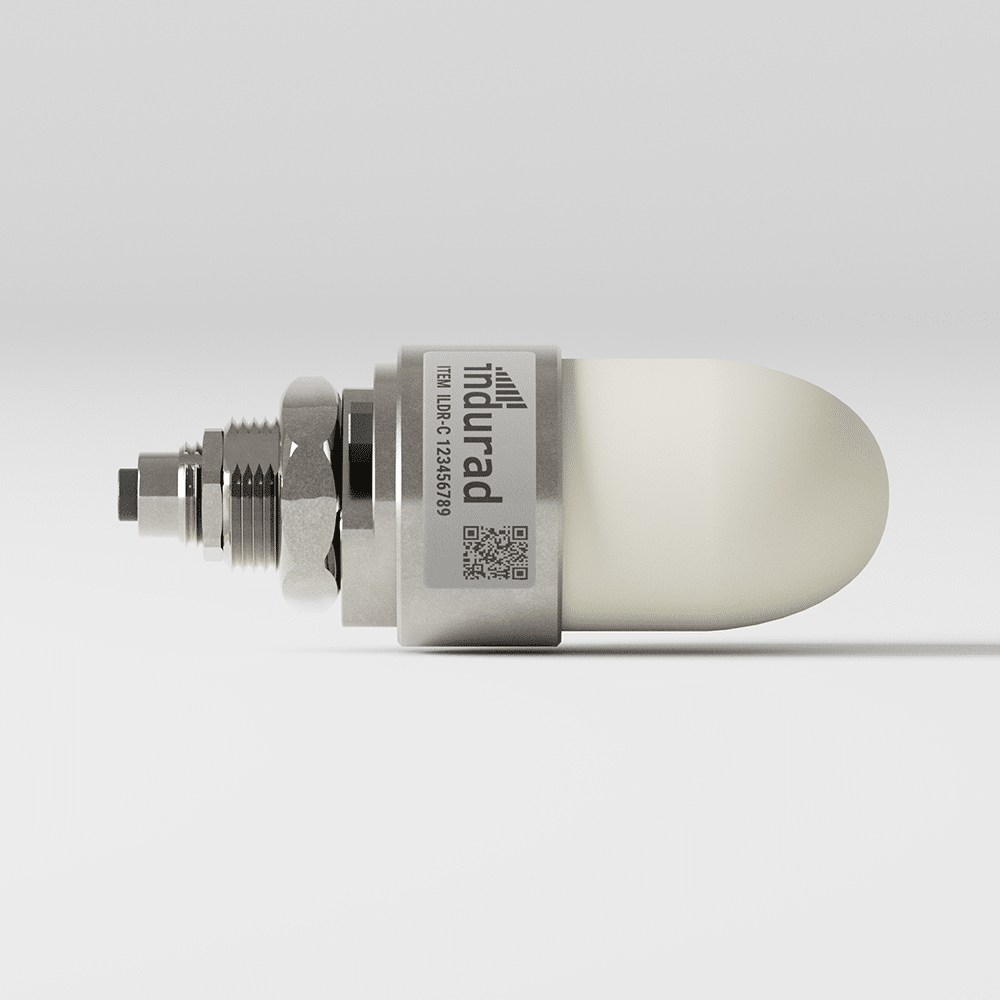

Measures distance to belt edges, reducing misalignment. Pair of two sensors included in iBeltALIGN module.

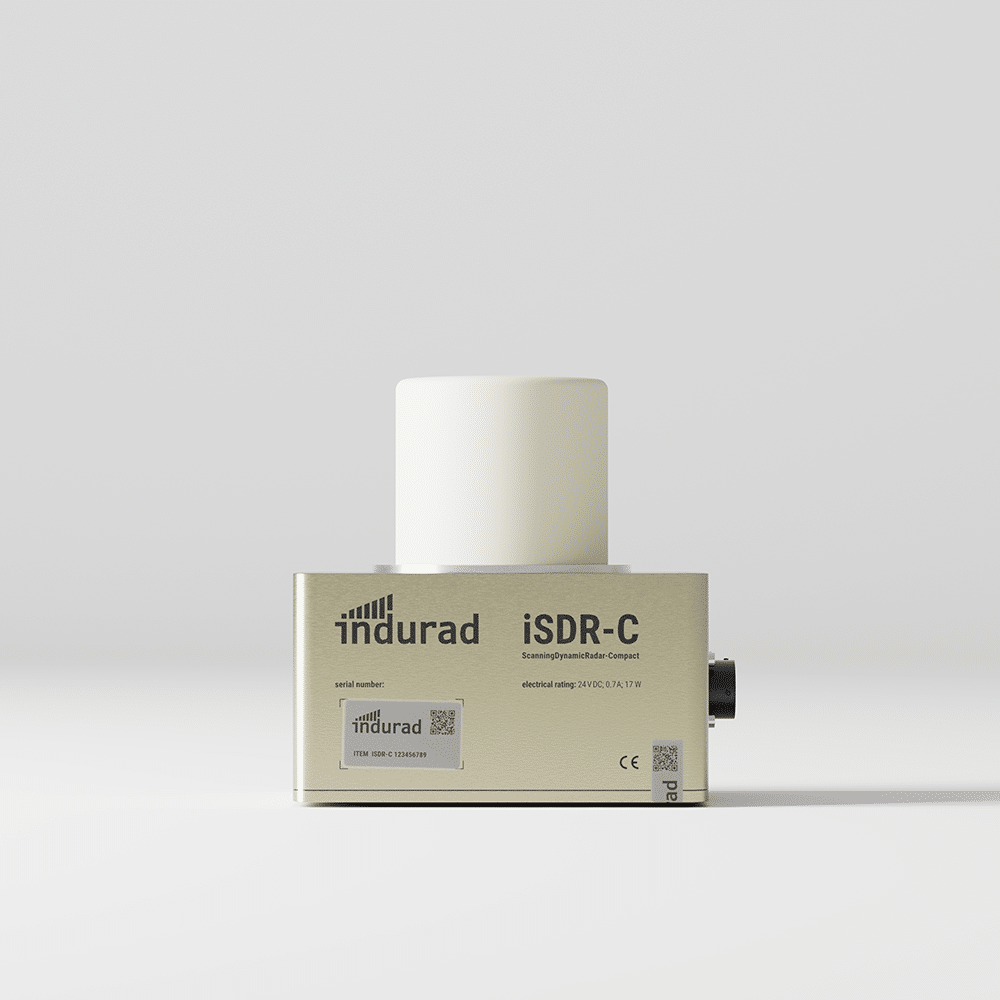

2D radar sensor measures conveyor belt cross-sectional profile, designed for mining and bulk material handling. Essential sensor for iBeltVOLUME module

Non-contact sensor measures material speed on conveyor belts, core component of iBeltSPEED module.

Houses RadarProcessingUnit-MiniHighpower for sensor signal processing, with 24V power supply, ethernet switch, and LTE modem. Offers easy installation and direct results.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationA 2D radar sensor is mounted above the conveyor and scans a cross section of the passing material. In combination with a fixed speed value of the passing material, a PLC or drive input signal – or at best in combination with our iDVR speed radar – a volume measurement is provided. In addition, height information and material distribution information can be obtained from this measurement.

exact measurement due to full surface coverage

enables safe operation and supports blending functionalities

Based on an indurad Doppler Velocity Radar, the system is able to measure the speed of the material passing underneath. This is the true material velocity value, which is the exact basis for high precision volume scanning. The bulk velocity measurement can also be used independently, for example to optimize belt speeds or to detect material slippage.

no-contact measurement without the need for recalibration

97% or better speed accuracy - much better than other measurement systems

Belt misalignment causes significant damage to the belt and reduces belt life. A belt that does not run well in the rollers consumes more power from the drives. The risk of spillage is increased. iBeltALIGN measures the position of the belt at a specific point or along the entire conveyor and is the basis for intervention and optimization.

first step to reduce wear on conveyor belts

increasing energy efficiency through correct alignment

Based on the belt alignment sensor, the system detects the freeboard on the belt to the left and right of the material. This information allows control and understanding of the material position on the belt, providing the basis for more efficient control of transfer points and material flow.

direct feedback of misaligned material dispatch after transfer point

detect unhealthy material position that increases wear and spillage

This set of specific software algorithms is the result of years of development. The advanced data package provides information on material distribution, center of gravity and height distributions for each instant and for historical data.

This allows for a better understanding of bulk processes and belt usage, while optimizing control.

learning, understanding and improving mine-wide belt usage

reduce spillage, avoid mistakes in blending processes and predictive maintenance

COUNTRY: Canada

MATERIAL: Oil Sand / Tar Sand

COMPONENTS: 2x iLDR-C, iSDR-C, iDVR, iRPU-F

DESCRIPTION

Volumetric flow measurement and belt alignment tracking.

Extreme environmental conditions (dirt, temperature).

COUNTRY: Chile

MATERIAL: Primary crushed copper ore

COMPONENTS: 12 x iDRRembedded, 12 x iDVR, OPC server

DESCRIPTION

Existing weight scales need to be replaced due to high maintenance costs. Significant improvements in secondary crushing process due to volume based process control with iBelt.

COUNTRY: Australia

MATERIAL: Iron Ore

COMPONENTS: 2 x iDRR, 1 x iDVR, 2 x iLDR, iRPU-O

DESCRIPTION

Iron ore volumetric measurement.

Belt misalignment measurement and material positon (freeboard).

Improved chute control, full utilization of conveyor belt to shiploader.

COUNTRY: China

MACHINE: IPCC equipment

MATERIAL: Coal

COMPONENTS: iDRR, iDVR, iRPU-I

DESCRIPTION

Belt with high inclination.

Steam coming from the coal.

Moving machinery, permanent vibration of belt, shocks.

COUNTRY: Canada

MATERIAL: Oil Sand / Tar Sand

COMPONENTS: iDRR, iDVR, iRPU-O

DESCRIPTION

Volumetric flow measurement on chain conveyor.

Measuring volume flow and speed to control mixing box.

Extreme weather conditions (snow, temperature).

COUNTRY: USA

MATERIAL: n/a

COMPONENTS: 2 x iDRR, iRPU-O

DESCRIPTION

iBelt mounted on tunneling machine to measure excavated material volume versus calculated quantity of excavated material (to avoid development of caverns).

COUNTRY: Australia

MATERIAL: Coal

COMPONENTS: 2 x iDRR, iRPU

DESCRIPTION

Volumetric measurement with height restriction on chain conveyor.

Explosion proof housings (iCEx/ATEX M2).

No overloading of belt any more due to improved process control.

COUNTRY: Canada

MATERIAL: Potash

COMPONENTS: iDRRembedded, iDVR

DESCRIPTION

iBelt (volume, speed) in potash mines may be bolt into roof.

Measures productivity of mine segment.

COUNTRY: USA

MATERIAL: Hard Coal

COMPONENTS: 2 x iLDR, iRPU-O

DESCRIPTION

Freeboard measurement in underground coal mine.

Allows for maximum utilization of belt.

Center of gravity measurement.

COUNTRY: Netherlands

MATERIAL: Coal

MACHINE: Barge loader

COMPONENTS: 2x iLDR-C

DESCRIPTION

iBelt measures belt alignment and material freeboard on boom belt, allowing for adapting machine control (guide plate positioning) to improve productivity, and to reduce wear.

COUNTRY: Australia

MATERIAL: Rocks

MACHINE: Track Renewal and Laying Machine

COMPONENTS: 3x iSDR-C and 3x iDVR

DESCRIPTION

iBelt measures and keeps track of reclaimed and distributed ballast material during track renewal.

COUNTRY: Chile

MATERIAL: Copper Ore

MACHINE: Tripper Car

COMPONENTS: iDRR, iDVR, iRPU-I

DESCRIPTION

Volume flow on the conveyor belt determines travelling speed of the tripper car, allowing for automation and optimized material blending.

COUNTRY: USA

MATERIAL: Lime Stone/Coal (combined stock pile)

MACHINE: A-Frame Reclaimer

COMPONENTS: iDRR, iRPU-O

DESCRIPTION

iBelt measures material flow directly after boom, allowing for adapting machine control (long travel speed and boom position) to improve productivity, and to reduce wear.

COUNTRY: Netherlands

MATERIAL: Coal

MACHINE: Reclaimer

COMPONENTS: iDRRembedded

DESCRIPTION

Volume flow measured directly behind reclaimer bucket wheel. Solution provides information to the reclaimer PLC system of the reclaimer, optimizing cutting depths and slew speed.

COUNTRY: Australia

MATERIAL: Iron Ore

MACHINE: Mixing System

COMPONENTS: 4 x iDRR, 4 x iDVR, iRPU-I

DESCRIPTION

Complex mixing process fully controlled by iBelt.

Allows for perfect mixing and thus improves downstream processes.

Significant savings for customer accomplished.

COUNTRY: Chile

MATERIAL: Wood Chips

COMPONENTS: iSDR, iDVR, iRPU-F

DESCRIPTION

Volume-Flow measurement of wet wood chips.

COUNTRY: Australia

MATERIAL: Coal

COMPONENTS: iDRR, iRPU-O

DESCRIPTION

Coal stacker controls volume flow, allows stacking of homogenious piles.

Input for dust reduction in stacking process.

COUNTRY: Australia

MATERIAL: Iron Ore

COMPONENTS: 2 x iLDR, iRPU-O

DESCRIPTION

iLDR contactless freeboard and belt misalignment measurement.

Up to 4000 Hz measurements with mm precision.

COUNTRY: Australia

MATERIAL: Iron Ore

COMPONENTS: iDRR, iDVR, 2 x iLDR, iRPU-O, iCam

DESCRIPTION

iBelt controls surge bin output (optimizing belt load), monitoring belt scale.

COUNTRY: Australia

MATERIAL: Iron Ore

COMPONENTS: iDRRembedded, iDVR, 2 x iLDR

DESCRIPTION

| Iron ore export terminal. iBelt measures out- and infeed of surge bin, optimizing the most critical process part during shiploading procedure. |

Conveyor belt flow & belt misalignment, condition monitoring & wear

Gyratory | Jaw | Crusher Vault

Tertiary

Tertiary | Cone Crusher

Apron & plate feeder 2D level and material volume

Screendeck performance and material yield measurement

Chute blockage detection and material flow monitoring

Level measurement, blockage detection and material flow monitoring

3D silo volume measurement + rathole detection monitoring

3D dome volume measurement, material tracking and feeder control

3D stockpile scanning, quality model and automation

3D stockpile scanning, quality model and automation

3D stockpile scanning, quality model and automation

Train loadout productivity increase by automation

Waggon unloader automation and material tracking

Stacker Automation, incl. 3D pile monitoring & material tracking

Material quality control and tracking, blending automation

Reclaimer automation and collision avoidance

Level9 collision avoidance for underground vehicles & personnel

Level9 collision avoidance for underground vehicles & personnel

IPCC automation and heavy machine positioning solutions

IPCC automation and heavy machine positioning solutions

Shiploader collision avoidance, 3D hatch scan and full automation

Horizontal and vertical boom CAS, 3D hatch scan and automation

Vessel detection and ship guidance system for berthing operations

Monthly payments, subscription services

Project based implementation as capital expenditure

Diverse management team driving customer success.

Cross-industry partner network for sales and service - always close to the customer.

company success story and recent developments transforming mining.

Join the Indurad family and develop your career in an exciting environment.

Learn about new developments and the shows and conferences we attend.

The core DNA of indurad. Learn more about the publicly funded RnD.

Hexagon Mining provides solutions for safer, more productive mining operations.

We use Google Language Translator Plugin that uses the free Google automatic machine translation.

Be aware that not all translations have to be correct and that your IP address will be transmitted to Google to receive the translations.

You can always return to our original English version.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information