Train Tracks

COUNTRY: Australia

MATERIAL: Rocks

MACHINE: Track Renewal and Laying Machine

COMPONENTS: 3x iSDR-C and 3x iDVR

DESCRIPTION

iBelt measures and keeps track of reclaimed and distributed ballast material during track renewal.

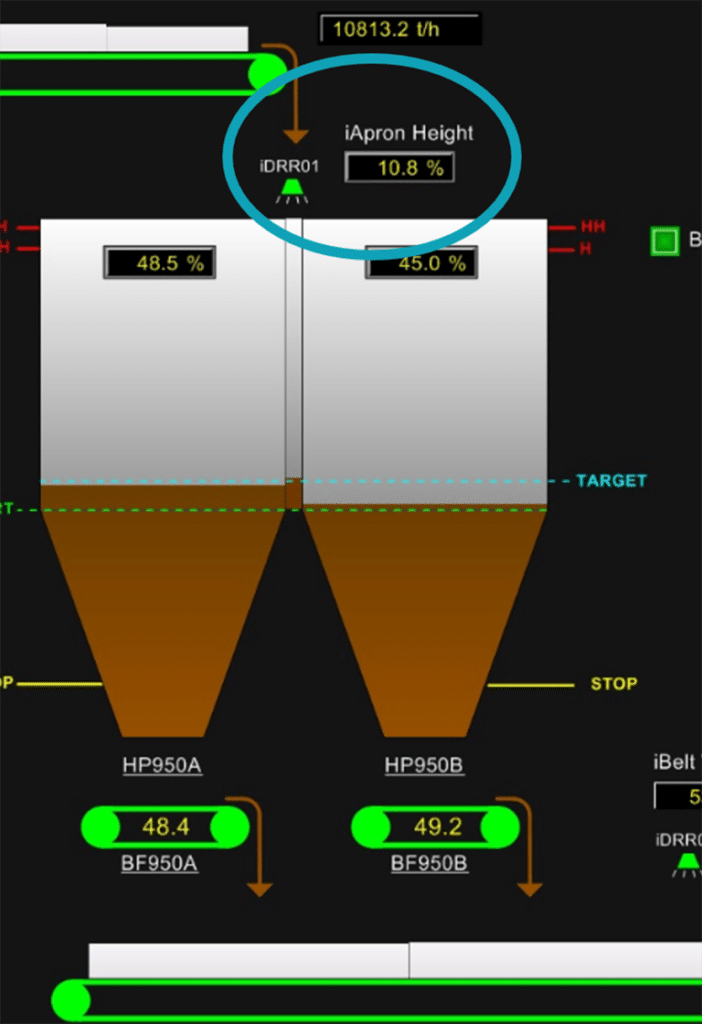

indurad’s iApron solution provides rapidly updated 2D profile information that your PLC can digest.

iApron is a highly reliable solution for monitoring filling height (including material distribution and surface contour) and volume in apron feeders, surge bins and comparable structures. The complex measurements are reduced to a PLC readable format.

The system uses a 2D radar sensor to measure the surface contour, which is then divided into different virtual bins by our software.

The level + average level of these virtual bins is provided to your PLC.

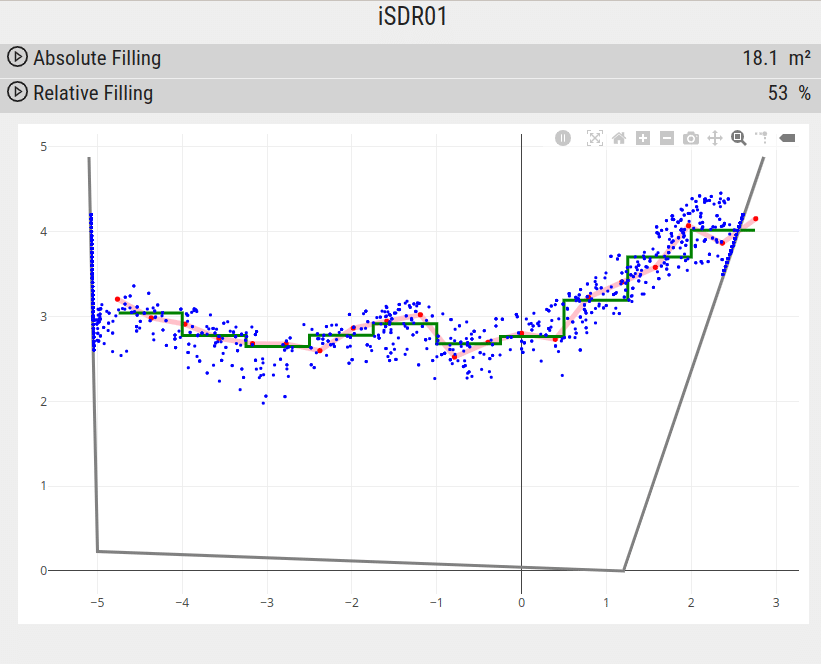

Rapid measurement for material level and distribution in 2D for Silos, Bunkers and Dump Pockets. Often replacing multipe 1D radar sensors at a fraction of the cost, or replacing unreliable laser or lidar sensors.

With iApron you receive data quality you can rely on.

iApron is used in railcar unloading stations to measure the material above the apron feeder. The PLC is provided with virtual bins. This information is used to control the feeder and maintain a protective layer of material (bed).

If during the reclaim process the material levels do not behave in a predicted way, actions can be taken to avoid blockages before it happens.

on a pole or inside the waggon tippler

not influenced by dust, rain, fog, snow, ice, ...

Easily installed above the reclaim feeders, the 2D or 3D radar sensor continuously monitors the amount and distribution of material above the draw points.

In addition to providing information relevant to feeder automation and material blending, the system is also widely used as a stockpile volume estimation system.

exact material informaton above reclaim feeders

much more reliable than 1D sensors

Dusty operations in surge bins are a perfect environment for the iApron solution. While usually update rates around 10Hz are the best option, iApron has more than enough performance reserves to measures changes in the surface countour, between the feeder and the dump point, with up to 25Hz.

knowing at any time when shiploader or loadout bin needs to be filled

strange material behaviour detected before bridges build or ratholes stop your operation

COUNTRY: Australia

MATERIAL: Rocks

MACHINE: Track Renewal and Laying Machine

COMPONENTS: 3x iSDR-C and 3x iDVR

DESCRIPTION

iBelt measures and keeps track of reclaimed and distributed ballast material during track renewal.

COUNTRY: Chile

MATERIAL: Wood Chips

COMPONENTS: iSDR, iDVR, iRPU-F

DESCRIPTION

Volume-Flow measurement of wet wood chips.

COUNTRY: Netherlands

MATERIAL: Coal

MACHINE: Barge loader

COMPONENTS: 2x iLDR-C

DESCRIPTION

iBelt measures belt alignment and material freeboard on boom belt, allowing for adapting machine control (guide plate positioning) to improve productivity, and to reduce wear.

COUNTRY: Canada

MATERIAL: Oil Sand / Tar Sand

COMPONENTS: 2x iLDR-C, iSDR-C, iDVR, iRPU-F

DESCRIPTION

Volumetric flow measurement and belt alignment tracking.

Extreme environmental conditions (dirt, temperature).

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSafety & Efficiency

A dust suppression system impaires visitoin of the human operator unloading vessels at at Port of Quebec. Indurad “restores” the operator’s vision using it’s 3D radar technology.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

indurad is a leader in making mining and dry bulk handling or processing easier and more cost effective. Based on our radar technology we offer various solutions and also sensors with OEM interfaces such as ROS2.

Conveyor belt flow & belt misalignment, condition monitoring & wear

Gyratory | Jaw | Crusher Vault

Tertiary

Tertiary | Cone Crusher

Apron & plate feeder 2D level and material volume

Screendeck performance and material yield measurement

Chute blockage detection and material flow monitoring

Level measurement, blockage detection and material flow monitoring

3D silo volume measurement + rathole detection monitoring

3D dome volume measurement, material tracking and feeder control

3D stockpile scanning, quality model and automation

3D stockpile scanning, quality model and automation

3D stockpile scanning, quality model and automation

Train loadout productivity increase by automation

Waggon unloader automation and material tracking

Stacker Automation, incl. 3D pile monitoring & material tracking

Material quality control and tracking, blending automation

Reclaimer automation and collision avoidance

Level9 collision avoidance for underground vehicles & personnel

Level9 collision avoidance for underground vehicles & personnel

IPCC automation and heavy machine positioning solutions

IPCC automation and heavy machine positioning solutions

Shiploader collision avoidance, 3D hatch scan and full automation

Horizontal and vertical boom CAS, 3D hatch scan and automation

Vessel detection and ship guidance system for berthing operations

Monthly payments, subscription services

Project based implementation as capital expenditure

Diverse management team driving customer success.

Cross-industry partner network for sales and service - always close to the customer.

company success story and recent developments transforming mining.

Join the Indurad family and develop your career in an exciting environment.

Learn about new developments and the shows and conferences we attend.

The core DNA of indurad. Learn more about the publicly funded RnD.

Hexagon Mining provides solutions for safer, more productive mining operations.

We use Google Language Translator Plugin that uses the free Google automatic machine translation.

Be aware that not all translations have to be correct and that your IP address will be transmitted to Google to receive the translations.

You can always return to our original English version.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information