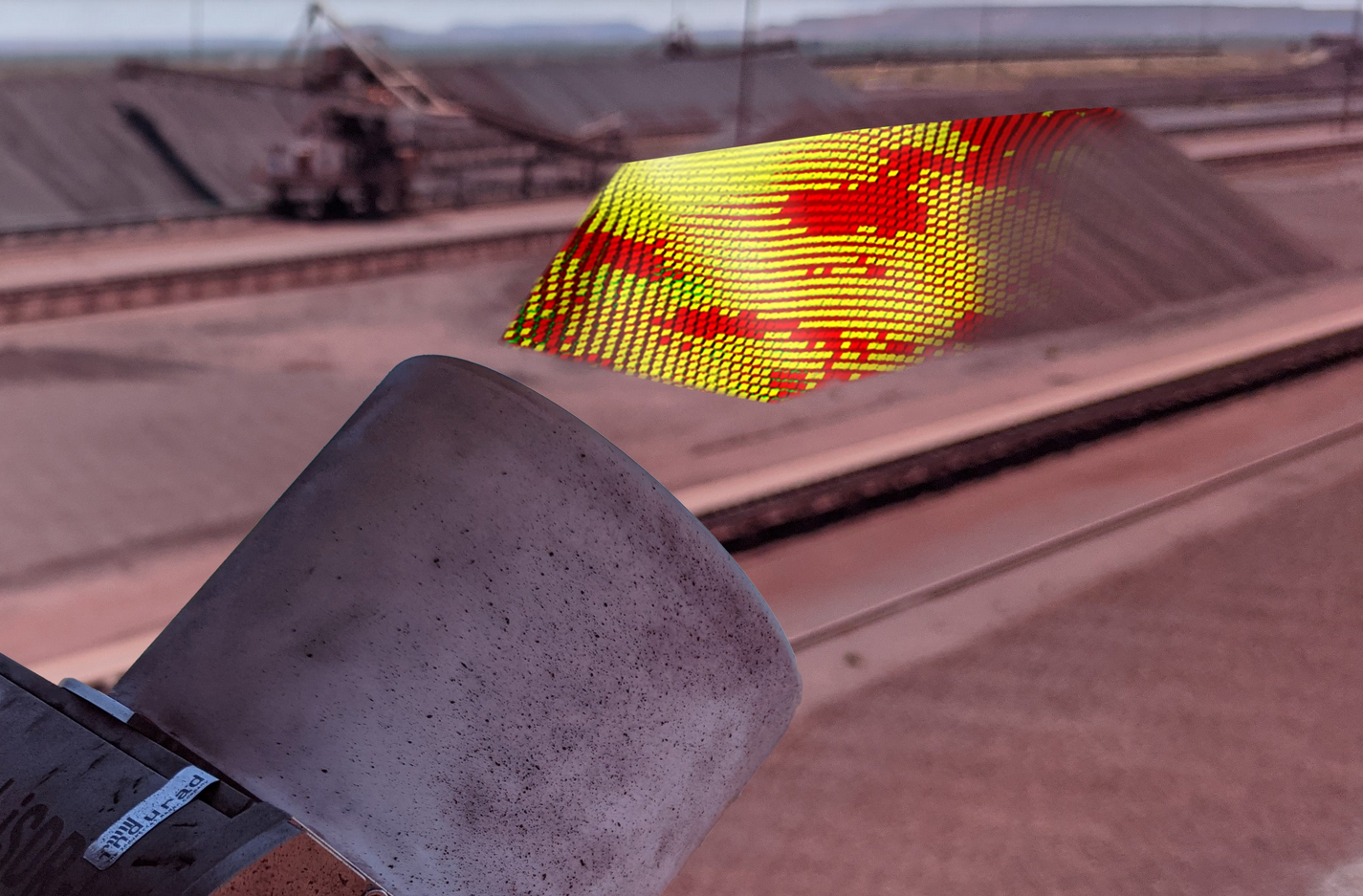

iStockpile4D™ radar machine vision system provides a Stockpile-as-a-Servicesolution for ore, salt or coal stockpile management from ROM to product pile. The digital-reality is based on actual3D radar scanning plus a next generation neutron generationelemental analyser exceeding mathematical modelling. Itreduces product and process variation and is unearthingsignificant multi-million dollar values in productivity andprofitability.

Reducing process variation

indurad’s iStockpile4D™ is a radar machine vision ‘Stockpile-as-a-Service’ solution for ore, salt or coal stockpile management from ROM to product pile. The digital-reality is based on actual 3D radar scanning plus a next generation neutron generation elemental analyser exceeding mathematical modelling. It reduces product and process variation and the company says is unearthing significant multi-million dollar values in productivity and profitability.indurad was already a pioneer being part of RioTinto’s Mine of the Future program some 10 years ago with smart instrumentation and machine vision in mine outload optimisation.

Today all 14 Rio Tinto Iron Ore (RTIO) mine sites in the Pilbara have been fitted with indurad technology, including an iStockpile4D and iLoadoutG5 solution at the flagship Gudai-Darri highly automated mine. Reik Winkel, indurad Executive Officer told IM: “indurad solutions are geometric measurement solutions feeding easy to digest data to the process control system and SCADA, where we assist with a global network of system integrators using Rockwell, Siemens and Schneider PLC, MES and SCADA systems beyond advanced views via Qt-based graphical engines with 4K HDMI output for remote operation centres or HTML5 web output on premise within the IT or OT network.” Mining is full of uncertainties and variance. indurad argues that while these cannot be eliminated – they can be significantly managed and mitigated. The indurad technology is focusing on this stack. “Our iCrusher allows the identification of oversize, our iStockpile5D allows monitoring and homogenisation of product quality and reduction of segregation. The maritime industry has been pioneering in the use of radar for adverse environmental conditions – indurad brought this success to mining allowing machine vision under dust, water suppression, fog and snow. iApron and iBelt allow reduction of spillage and avoidance of blocked chutes as well as lifetime extension of feeders. Finally,teleremote operation and full automation with iStacker and iReclaimer allow management of the human factor.”

Please read the article or download it now and visit International Mining.